Want to know what is floating slab and its construction process? Building a solid foundation is crucial in any construction project, and one innovative approach gaining popularity is the use of floating slabs.

In this article, we’ll delve into the construction, advantages, and disadvantages of floating slabs, providing you with valuable insights to make informed decisions for your next project.

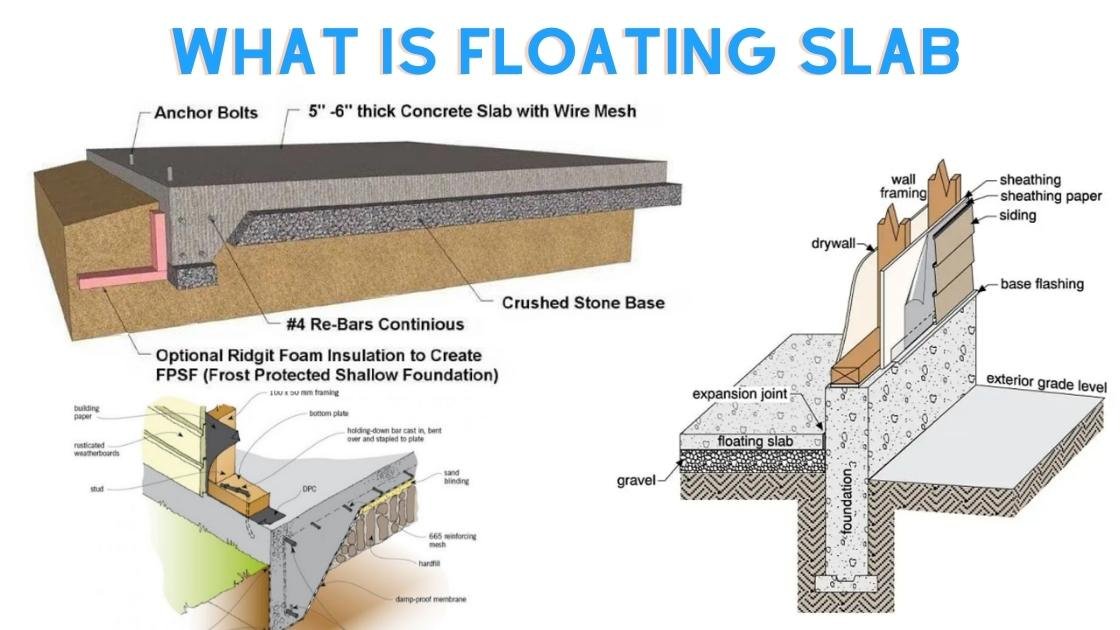

Floating Slab Construction

Constructing a floating slab involves using materials suitable for creating a stable and level foundation. The exact materials may vary based on the specific requirements of your project, but here is a general list of materials commonly used for constructing a floating slab:

- Concrete Mix:

- Portland cement

- Sand

- Gravel or crushed stone

- Reinforcement:

- Rebar (reinforcing bar) for structural strength

- Formwork:

- Plywood or oriented strand board (OSB)

- Lumber for framing the formwork

- Vapor Barrier:

- Polyethylene sheeting to prevent moisture penetration

- Subgrade Preparation:

- Crushed stone or gravel for a stable base

- Compaction Equipment:

- Plate compactor or a vibrating compaction tool for compacting the subgrade

- Expansion Joint Material:

- Foam or rubber expansion joint material to allow for movement and prevent cracks

- Concrete Finishing Tools:

- Bull float, trowels, edgers for finishing the concrete surface

- Concrete Sealer:

- Optional, but recommended for protecting the concrete surface

- Safety Equipment:

- Safety glasses

- Gloves

- Steel-toed boots

- Dust mask

- Mixing and Pouring Equipment:

- Concrete mixer or mixing tools

- Wheelbarrow or concrete buggy for transporting concrete

- Leveling Tools:

- Laser level or a transit for ensuring a level surface

- Construction Adhesive or Anchors:

- If attaching the slab to existing structures, adhesive or anchors may be needed

- Construction Joint Materials:

- Dowels or other materials for creating construction joints if needed

Recommended for you:

- What is Post Tension Slab – Its Advantages and Disadvantages

- What is DPC? Damp Proof Course

- What is a Contractor: Types, Responsibility, Liability & Importance in the Construction Industry

Advantages of Floating Slab

Floating slabs, also known as slab-on-grade foundations, offer several advantages in certain construction scenarios. Here are some of the key advantages:

- Cost-Effective: Floating slabs are often more cost-effective than traditional foundations since they require less excavation and materials.

- Simplified Construction: The construction process for floating slabs is generally simpler and quicker compared to other foundation types, saving time and labor costs.

- Suitable for Expansive Soils: Floating slabs are well-suited for areas with expansive soils that may experience swelling and shrinking, as they can move with the soil without causing structural issues.

- Minimized Risk of Frost Heave: In cold climates, where frost heave can be a concern, floating slabs can be designed to minimize the risk of heaving by extending below the frost line.

- Versatility: Floating slabs are versatile and can be used for various types of structures, including residential homes, small commercial buildings, and storage sheds.

- Reduced Risk of Differential Settlement: Since floating slabs distribute the load uniformly over a large area, they can help minimize the risk of differential settlement, which can be a concern in areas with varying soil conditions.

- Energy Efficiency: The thermal mass of the concrete in a floating slab can contribute to energy efficiency by helping to regulate indoor temperatures and reduce heating and cooling costs.

- Easier Accessibility: Floating slabs provide a flat, level surface, making them accessible for people with mobility challenges. This can be particularly beneficial in residential construction.

- Adaptability to Sloping Sites: Floating slabs are well-suited for construction on sloping sites, as they can be designed to accommodate changes in elevation without the need for extensive excavation.

- Minimal Disturbance to Surroundings: The construction of floating slabs typically involves minimal disturbance to the surrounding environment, making them suitable for projects in established neighborhoods.

- Reduced Risk of Termite Infestation: Elevated slabs can reduce the risk of termite infestation compared to traditional foundations that may provide a direct pathway for termites to access the structure.

Disadvantages of Floating Slab

While floating slabs have their advantages, they also come with certain disadvantages that should be considered in specific construction situations. Here are some of the potential drawbacks of floating slabs:

- Limited Load-Bearing Capacity: Floating slabs may have limitations in terms of supporting heavy loads, making them less suitable for structures with significant weight requirements.

- Vulnerability to Ground Movement: In areas prone to seismic activity, the lack of deep anchoring may make floating slabs more susceptible to ground movement during an earthquake.

- Moisture Issues: Without proper moisture protection, floating slabs can be susceptible to moisture penetration from the ground, leading to issues such as mold growth and concrete degradation.

- Not Suitable for High Water Tables: In locations with high water tables, floating slabs may be more prone to hydrostatic pressure, which can lead to moisture-related problems and structural issues.

- Temperature Sensitivity: Floating slabs may be more susceptible to temperature-related issues, such as cracking, especially in regions with extreme temperature variations.

- Difficulty in Repairs: If a floating slab settles or experiences structural issues, repairs can be challenging and may require lifting the entire structure to address underlying problems.

- Not Ideal for Multi-Story Buildings: Floating slabs may not be suitable for multi-story buildings where a more robust foundation system is typically required to support the additional weight and structural demands.

- Insulation Challenges: Providing insulation beneath a floating slab can be more challenging compared to other foundation types, potentially leading to energy inefficiencies.

- Complex Site Preparation: Achieving proper compaction of the subgrade is crucial for the success of a floating slab. In some cases, extensive site preparation may be necessary to ensure a stable foundation.

- Not Ideal for Unstable Soils: In areas with highly unstable or compressible soils, floating slabs may not provide adequate support, and alternative foundation solutions may be more suitable.

- Potential for Differential Settlement: While floating slabs aim to distribute loads evenly, there is still a risk of differential settlement, particularly if the subgrade is not uniformly compacted.

Comparison with Other Foundation Types

Comparing floating slabs with other foundation types involves considering various factors such as cost, suitability for different soil conditions, load-bearing capacity, and construction complexity. Here’s a comparison between floating slabs and some common foundation types.

| Aspect | Floating Slab | Trench Foundation (Strip Foundation) | Pile Foundation | Crawl Space Foundation | Basement Foundation | Mat Foundation | Pier Foundation |

|---|---|---|---|---|---|---|---|

| Cost | Cost-effective | Moderate to high cost | Higher cost | Higher cost than floating slabs | Higher cost, especially for full basements | Higher cost | Higher cost |

| Soil Suitability | Suitable for stable soils | Suitable for various soil types | Suitable for unstable soils | Suitable for flat terrain | Suitable for various soil types | Suitable for stable soils | Suitable for sloping terrain |

| Load-Bearing Capacity | Limited | Better than floating slabs, but depends on design | Excellent | Better load-bearing capacity | Excellent load-bearing capacity | Excellent load-bearing capacity | Good load-bearing capacity |

| Vulnerability to Ground Movement | Yes | Potential for differential settlement, especially in expansive soils | Yes, but can resist ground movement in certain designs | No | No | Potential for differential settlement | Effective in resisting ground movement |

| Complexity of Construction | Simple | More complex than floating slabs | Complex | Moderate complexity | Complex | Complex | Moderate complexity |

| Moisture Issues | Potential for moisture issues | Potential for moisture issues, especially in clay soils | Depends on design, potential for moisture issues | Less susceptible to moisture, better ventilation | Potential for moisture in basements | Depends on design, potential for moisture issues | Potential for moisture issues |

| Usable Space | Limited usable space | Depends on design, potential for usable space beneath structure | Usable space in certain designs | Usable space with access for utilities | Adds usable living space | Depends on design, potential for usable space | Potential for usable space depending on design |

| Insulation Possibilities | Limited | Depends on construction, may allow for insulation | Good insulation possibilities | Better insulation possibilities | Better insulation possibilities | Good insulation possibilities | Limited insulation possibilities |

Structural Integrity and Design Considerations

Structural integrity and design considerations for a floating slab involve specific factors that address the unique characteristics of this type of foundation. Here are key considerations for ensuring the structural integrity of a floating slab:

Soil Assessment:

Conduct a thorough soil analysis to understand the soil’s bearing capacity, settlement characteristics, and potential for expansion or contraction. Ensure that the soil can adequately support the load of the structure.

Foundation Depth:

Determine the appropriate depth for the floating slab based on soil conditions. Adequate depth helps minimize the impact of seasonal changes, including freeze-thaw cycles and soil moisture variations.

Reinforcement:

Incorporate reinforcement, such as rebar, within the concrete mix to enhance the tensile strength of the slab. Proper reinforcement helps resist cracking and increases overall structural strength.

Concrete Mix Design:

Use a concrete mix with appropriate compressive strength, workability, and durability. Consider factors like the local climate, exposure to moisture, and the potential for temperature fluctuations.

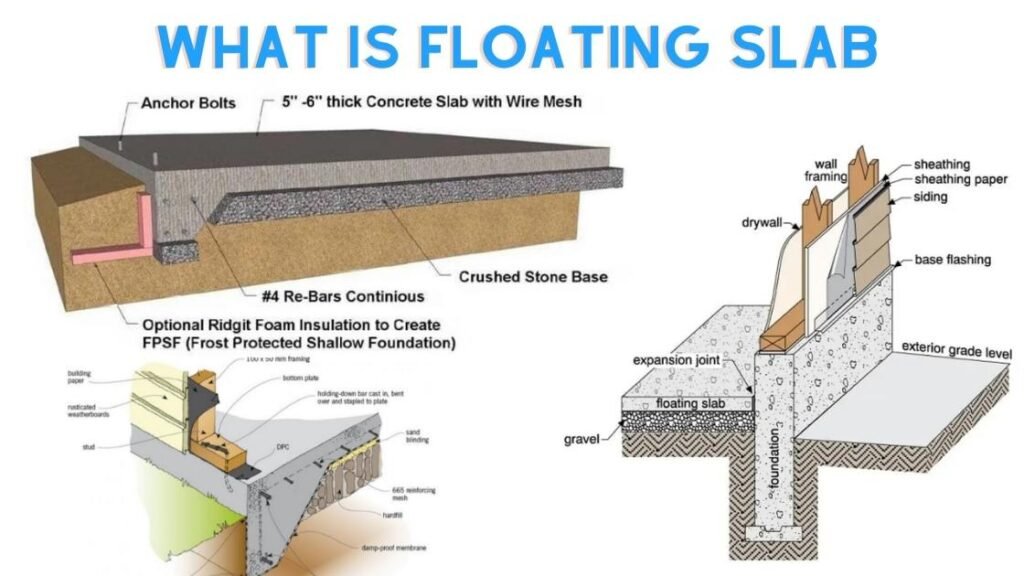

Vapor Barrier:

Install a vapor barrier beneath the floating slab to prevent moisture migration from the ground into the concrete. This helps mitigate potential moisture-related issues, such as mold growth and concrete deterioration.

Expansion Joints:

Include expansion joints in the design to accommodate temperature-related movements and prevent the development of cracks. Properly spaced expansion joints allow the slab to expand and contract without compromising its structural integrity.

Compaction of Subgrade:

Ensure thorough compaction of the subgrade before pouring the concrete. Proper compaction provides a stable base for the floating slab and helps prevent settlement issues.

Leveling and Slope Considerations:

Achieve a level surface for the floating slab to ensure uniform load distribution. Consider slope requirements for drainage purposes, especially if the slab is used for a larger structure.

Edge Support:

Provide adequate edge support for the floating slab to prevent edge settlement. This can be achieved through the use of thickened edges or grade beams.

Construction Tolerance:

Maintain construction tolerances and specifications during the pouring and finishing of the concrete to ensure the slab meets the design criteria.

Moisture Protection:

Apply appropriate sealers or coatings to the finished slab to protect against moisture infiltration and enhance the durability of the concrete.

Insulation Considerations:

If required, incorporate insulation beneath the floating slab to improve energy efficiency and protect against temperature-related issues.

Geotechnical and Structural Engineering Input:

Seek input from geotechnical and structural engineers to ensure that the floating slab design is suitable for site-specific conditions and meets safety standards.

Construction Quality Control:

Implement quality control measures during construction, including inspections and testing, to identify and address any deviations from the design specifications.

Considering these factors during the design and construction of a floating slab foundation contributes to its structural integrity and long-term performance. Collaborating with qualified professionals, including geotechnical and structural engineers, is crucial to ensuring a successful and robust floating slab foundation.

Common Misconceptions of Floating Slab

Several misconceptions exist regarding floating slabs, and it’s important to address them to promote accurate understanding. Here are some common misconceptions about floating slabs:

Misconception: Floating Slabs “Float” Above the Ground.

Clarification: While the term “floating” may suggest detachment, a floating slab is actually in direct contact with the ground. The term refers to the fact that it doesn’t have deep footings or piers, but it is firmly anchored to the ground.

Misconception: Floating Slabs Can Float Away.

Clarification: The name “floating slab” can be misleading, as it might lead people to believe that the slab can move or float away. In reality, floating slabs are securely anchored to the ground and do not float or move once properly constructed.

Misconception: Floating Slabs are Suitable for All Soil Types.

Clarification: While floating slabs are versatile, they may not be suitable for all soil types. Site-specific factors, such as soil stability and bearing capacity, should be considered. In some cases, soil improvement or alternative foundation types may be necessary.

Misconception: Floating Slabs are Only for Small Structures.

Clarification: Floating slabs are used in a variety of structures, including homes, garages, and small commercial buildings. However, their use is not limited to small structures. Engineers can design floating slabs for larger structures based on the specific project requirements.

Misconception: Floating Slabs are Prone to Cracking.

Clarification: Properly designed and constructed floating slabs are not inherently prone to cracking. Factors such as appropriate reinforcement, concrete mix design, and the inclusion of expansion joints can minimize the risk of cracking.

Misconception: Floating Slabs Always Have Moisture Issues.

Clarification: While moisture issues can occur if not properly addressed, the use of vapor barriers, adequate drainage, and proper site preparation can help prevent moisture-related problems in floating slabs.

Misconception: Floating Slabs Provide No Insulation.

Clarification: While floating slabs may not inherently provide insulation, additional insulation materials can be incorporated beneath the slab to improve energy efficiency. It’s a design consideration rather than a limitation of floating slabs.

Misconception: Floating Slabs Are Temporary Solutions.

Clarification: Floating slabs are permanent foundations commonly used in various construction projects. They are not temporary solutions and can provide long-lasting support when designed and constructed appropriately.

Misconception: Floating Slabs Always Result in Uneven Floors.

Clarification: Proper construction practices, including site preparation and compaction, can result in a level and stable floating slab. The misconception of uneven floors may stem from inadequate construction rather than inherent issues with floating slabs.

Misconception: Floating Slabs Offer No Structural Support.

Clarification: Floating slabs are designed to provide structural support for buildings. While they may have limitations in terms of load-bearing capacity compared to deep foundations, they are suitable for a wide range of structures when designed correctly.

It’s essential to consult with professionals and follow best practices during the design and construction of floating slabs to ensure they meet safety standards and are appropriate for the specific project requirements.

Conclusion on Floating Slab

The floating slab is a versatile and cost-effective foundation option suitable for various construction projects. Despite its name, it firmly anchors to the ground, providing stable support for structures.

While commonly associated with smaller buildings, properly engineered floating slabs can also support larger structures in diverse soil conditions. Key considerations for structural integrity include soil assessment, proper foundation depth, reinforcement, and moisture protection.

Consulting with professionals ensures that the design meets safety standards and aligns with the project’s unique requirements. In essence, floating slabs offer a reliable foundation solution when designed and constructed with precision.